Share to

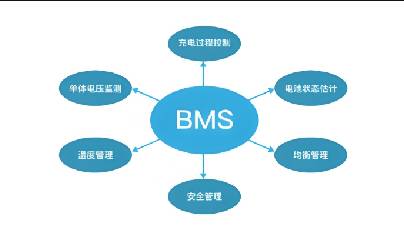

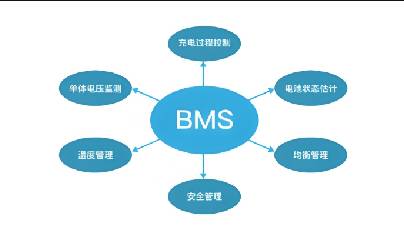

BMS (Battery Management System) is a key component and plays a core role in

energy storage system, responsible for monitoring and managing the status, power, temperature, and other information of battery packs to ensure the safe and stable operation of batteries. The docking between BMS and the entire energy storage system is usually achieved through data communication interfaces. The following are the general operational steps for the integration of BMS with the entire energy storage system:

1、 Integration of BMS and energy storage system

1. Selection of communication interface: BMS and other devices in the energy storage system (such as PCS, EMS, etc.) are connected through standard communication interfaces, common communication interfaces include CAN bus, RS485, Ethernet, etc. Choosing a suitable communication interface requires consideration of factors such as data transmission rate, stability, and reliability.

2. Data exchange protocol: BMS and other devices in the energy storage system need to follow a certain data exchange protocol to ensure the correct transmission and parsing of data. These protocols may include battery information transmission protocols, charge and discharge control protocols, etc.

2、 Operation steps

1. BMS initialization: First, initialize and set the BMS, including the configuration of battery pack parameters, communication interface settings, etc. Start the energy storage system and wait for BMS connection.

2. System connection: Firstly, through the communication interface, it is necessary to connect the hardware devices of the BMS (such as sensors, control modules, etc.) to the battery pack and related equipment. During this process, device authentication and handshake operations may be required. It is also necessary to ensure the correct installation and wiring of hardware equipment, and ensure the accuracy and stability of data transmission.

3. Set parameters: Set relevant parameters in the BMS system, including battery pack model, rated capacity, voltage range, charging and discharging limits, etc. Configure different parameters according to actual situations.

4. Data collection: The BMS system will regularly collect various data of the battery pack, such as voltage, current, temperature, SOC (battery charging status), SOH (battery health status), etc., to monitor the operation status of the battery pack.

5. Data transmission: Once the connection is successfully established, the BMS begins to send battery pack status information (such as battery level, voltage, temperature, etc.) to other devices in the energy storage system. At the same time, BMS also receives control instructions and data requests from other devices, and parses these instructions and requests. The BMS transmits the collected data to the entire energy storage system through communication interfaces, and the control system can operate, control, and adjust based on this data.

6. Charge and discharge control: Based on the operating strategy of the energy storage system and the status information of the battery pack, the BMS sends charge and discharge control commands to the PCS. These instructions may include parameters such as charging current, discharging current, charging and discharging cut-off voltage, etc.

7. Fault diagnosis: During the operation of the energy storage system, the BMS system is able to monitor the health status of the battery pack and detect possible abnormal situations (such as overcharging, over discharging, high temperature, etc.) by issuing alarms or warning messages. Once an abnormal situation is detected, the entire energy storage system can diagnose and handle faults based on the alarm information of the BMS.

8. Data storage: BMS stores the status information and operational data of the battery pack on local or remote servers for subsequent analysis and reporting. Meanwhile, BMS can also generate various reports as needed, such as power reports, temperature reports, etc.

9. Operation control: The entire energy storage system can operate and control based on the data provided by BMS, adjust charging and discharging power, protect battery packs, optimize system operation, etc.

Through the above operations, BMS can interface with the entire energy storage system and achieve data communication and control. This can ensure the safe operation of the battery pack and improve the reliability and efficiency of the system. In practical operation, there may be some differences in details based on the specific configuration requirements of the energy storage system and BMS system, and flexible adjustments need to be made according to the specific system configuration and application scenarios. In practical applications, additional factors may need to be considered, such as system security, scalability, maintainability, etc.